Economical Lift Repair Near Me: Professional Service Technicians at Your Solution

Economical Lift Repair Near Me: Professional Service Technicians at Your Solution

Blog Article

Diving Into the Globe of Elevators: Usual Concerns Dealt With by Various Lift Devices

As we browse via the vertical transportation systems of modern-day structures, elevators stand out as an essential element of our everyday lives. From hydraulic elevators to traction systems and machine-room-less designs, each lift kind comes with its set of typical problems.

Hydraulic Elevators

Hydraulic lifts, often preferred for low-rise buildings, utilize fluid pressure to control the activity of the elevator auto (lift repair companies). This mechanism includes a hydraulic pump pressing oil right into a cyndrical tube, causing the elevator to relocate the desired direction. While hydraulic elevators are understood for their silent and smooth operation, they do come with their own set of typical concerns

One widespread trouble with hydraulic elevators is oil leak. The seals in the hydraulic system can break over time, resulting in oil seepage. This not just develops a mess yet can additionally influence the lift's efficiency if left unaddressed. In addition, concerns with the control system, such as faulty valves or a malfunctioning pump, can cause disruptions in the elevator's movement.

Normal upkeep and punctual repair services are essential to ensure the smooth performance of hydraulic lifts. By addressing these usual concerns proactively, structure proprietors can lessen downtime and make sure the security and effectiveness of their vertical transportation system.

Traction Lifts

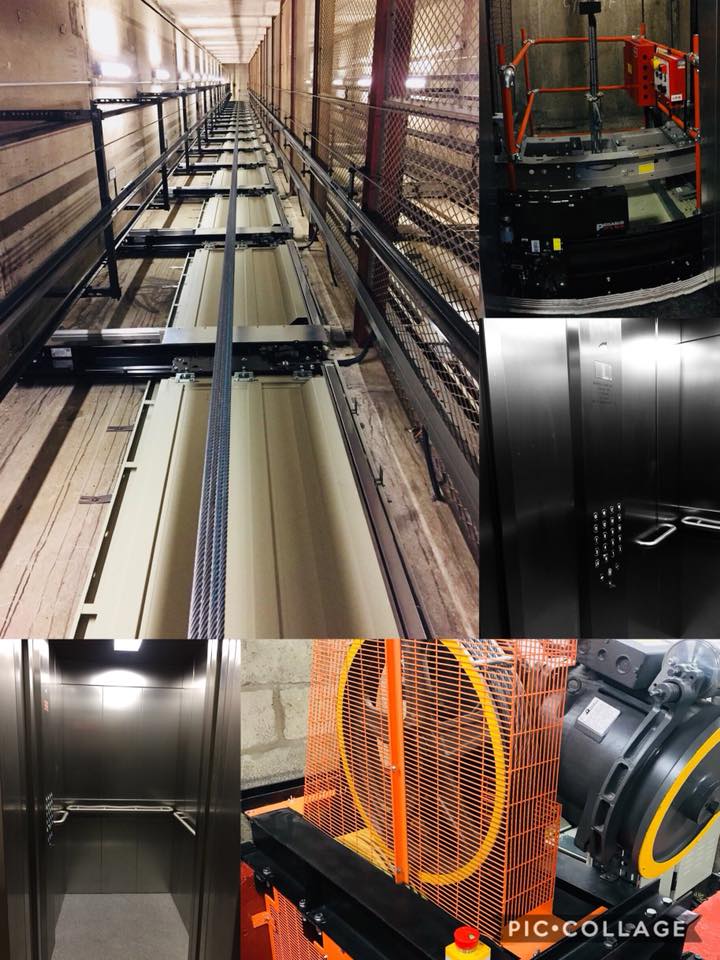

When taking into consideration upright transport systems in buildings, one more common type aside from hydraulic elevators is the traction lift. Grip elevators operate using a system of ropes and counterweights that move the elevator car by grasping onto the hoist ropes. This device permits smoother and faster vertical transportation compared to hydraulic systems.

Among the typical problems faced by grip lifts is rope wear. The consistent activity of the ropes within the grip system can cause damage over time, possibly creating the elevator to breakdown or come to be dangerous for use. Regular evaluations and upkeep of the ropes are necessary to ensure the elevator's proper performance and security.

One more problem that grip lifts may run into is associated to the control system. Troubles with the control system can result in issues such as unpredictable movement, hold-ups in reaction times, or perhaps complete shutdowns. Normal testing and maintenance of the control system are essential to avoid such issues and make sure the lift's reliability.

Machine-Room-Less (MRL) Lifts

Among the crucial elements of MRL lifts is the small gearless traction equipment that is mounted within the hoistway. This device efficiently drives the lift automobile without the need for cumbersome devices found in typical grip elevators. In addition, MRL elevators typically make use of a counterweight system to stabilize the automobile, further improving their energy effectiveness.

Despite their benefits, MRL lifts may encounter challenges associated to repair and maintenance as a result of the confined space for tools installation. Availability for servicing parts within the shaft can be limited, needing specialized training for professionals. Proper maintenance timetables and regular assessments are crucial to guarantee the ongoing smooth operation of MRL elevators.

Overloading and Weight Limitation Issues

Are lifts equipped to deal with excess weight tons effectively and securely? Overloading and weight limitation concerns are crucial worries in lift operations. Elevator makers layout raises with specific weight capacities to make sure guest safety and devices durability. Going beyond these weight restrictions can result in disabled platform lifts prices uk numerous issues, consisting of mechanical failings, hold-ups, and safety and security threats.

When lifts are strained, it puts excessive strain on the electric motor, cords, and other components, possibly creating break downs or malfunctions. Safety and security devices such as sensors and overload sensors are in area to stop lifts from moving if they spot excess weight. Additionally, going beyond weight limitations can lead to raised energy consumption and damage on the elevator system.

To mitigate straining problems, building supervisors ought to plainly show weight limits in lifts and inform occupants on the relevance of adhering disabled platform lifts prices uk to these constraints - lift repair companies. Routine maintenance checks by qualified specialists can additionally help make certain that lifts are operating within secure weight parameters. By addressing overloading and weight limitation issues proactively, structure proprietors can improve lift safety and performance

Electrical System Failings

Going beyond weight limitations in elevators can not just lead to mechanical problems yet likewise possibly add to electric system failures within the lift framework. Electrical system failings are a vital concern in elevator procedure, as they can create unforeseen closures, malfunctions, or also safety dangers. One common electric concern is the getting too hot of components because of too much current flow triggered by overwhelming the lift beyond its capability. This can bring about damage to the control, electrical wiring, or electric motor systems, resulting in expensive fixings and downtime.

Normal upkeep and evaluations are crucial to recognize and attend to potential electric issues without delay, making certain the effective and safe procedure of elevator systems. By sticking to weight restrictions and carrying out routine electric system checks, building proprietors can alleviate the risk of electric failings in elevators.

Verdict

Hydraulic elevators, typically preferred for low-rise buildings, use fluid stress to manage the motion of the lift car.When taking into consideration vertical transport systems in buildings, an additional usual type aside from hydraulic elevators is the grip elevator. Traction elevators operate making use of a system of ropes and counterweights that move the lift cars and truck by grasping onto the hoist ropes. Unlike typical lifts that call for a different maker space to house the devices, MRL lifts integrate many of the components within the shaft, getting rid of the requirement for a dedicated equipment room.In verdict, elevators deal with usual concerns such as hydraulic malfunctions, traction system failures, and electrical system problems.

Report this page